Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Learning & Resources » Case Studies » Cold Freezer Soil Stabilization and Concrete Re-leveling

In 2019 the freezer began to present cracks in different areas. By the end of year 2020, the two concrete slabs that make up the freezer began to sink from the corners. This could be seen from the legs of the racks suspended. The sinking of the floor could be seen from the gates of the freezer.

There is condensation towards the hydraulic base, passing the layer of thermal insulation and the differential expansions of the soils due to increases in humidity. When freezing, this has caused cracks in the slab which in turn has caused the vicious circle of increasing condensation. With this expansion, greater cracks and differential elevation in the slab of the ultra cool room have occurred.

To reduce vertical forces to the ground and reduce the risk of structural damage, it was necessary to restore and increase the load bearing capacity of the soil by injecting water-insensitive, pre-expanded FillFoam® and HMI 402 polyurethane near the surface to properly re-level the concrete slabs. The injection of polyurethane is working as thermal insulation. HMI polyurethane injections were completed from midnight to 6 AM.

Injection of high density FillFoam® and hydro-insensitive HMI 402 polyurethane was completed to re-level and increase insulation. This will reduce the clients electrical costs by 25% without disturbing operations.

The key to success with this project was engineering. Sophisticated surveys helped engineers understand what was below ground and how the structure above ground was behaving. Understanding the cause and effect of the failures lead the engineers to a custom and complete repair solution.

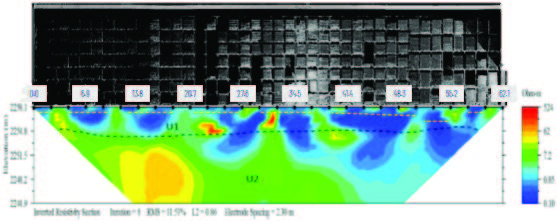

Vectorial survey of the racking with Electrical Resistivity testing below. This test sends an electrical current through a series of probes in the ground. How the current behaves as it returns to the probes can identify what is underground. Various soils, voids and moisture can be identified when this data is evaluated.

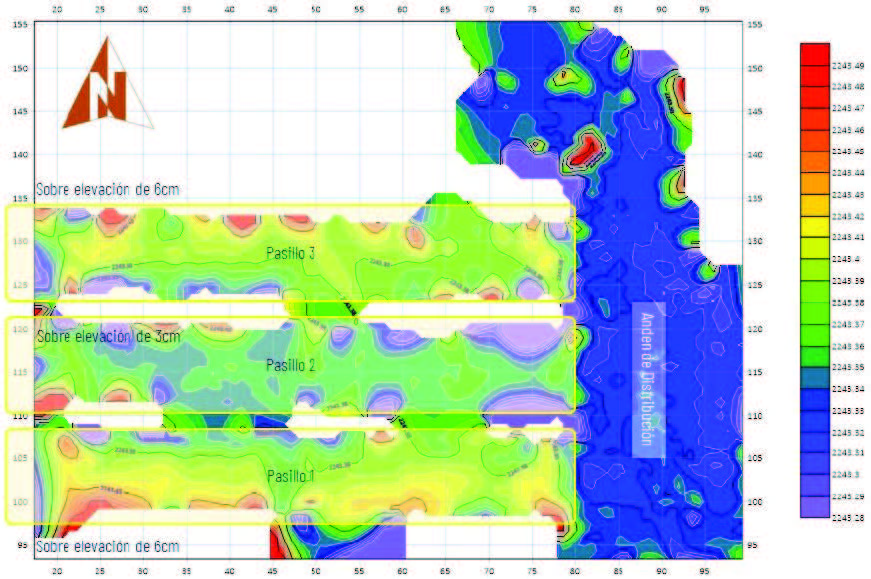

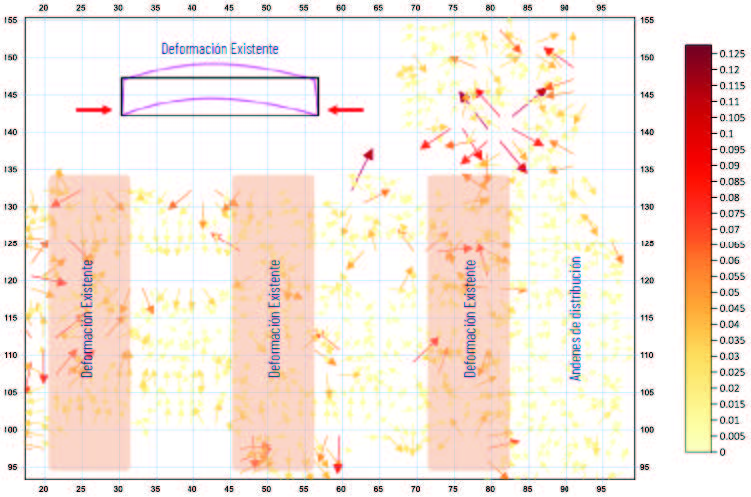

The Robotized Vectorial Surveys take billions of ‘points of reference’ that can be processed to review different aspects of the survey.

In View #1, it will look like a picture made of dots. This can be used as an interactive image to see from any angle. Each dot can be measured and evaluated to identify structural deficiencies.

View #2 looks like a heat map that shows settlement. The purple or blue show the most settlement. While areas in red, have had little to no settlement.

View #3 has arrows that represent slope. If you were to pour water on the slab, this is where it would flow. Areas with arrows pointing in from different directions represent a low point or zone where settlement has occurred.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!