Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Equipment » Industry Leading Polyurethane » HMI Hydrofoam Line

HMI is Proud to Introduce the BEST Hydro-Insensitive Foam on the Market

HMI foam is Hydro-insensitive because it forms high quality foam even in the presence of water. This includes during the injection, reaction, and curing phases. Foam that fails during the injection phase will leave the surrounding water cloudy, signifying that the raw chemicals have dissolved into the water. Foam that fails during the reaction phase simply won’t produce good foam. The foam may be left spongy, soft, and crumbly when water is present. Foam that fails in the curing phase won’t hold up. It may look like good foam at first, but will shrink over time.

HMI is proud to introduce the only true hydro-insensitive foam, a product that stands up in all three phases, the foam of choice for deep injection and seawall repair jobs.

HydroFoam was specially developed to resist hydrolysis- a chemical process in which water breaks down foam overtime causing the foam to shrink. Designed to not only set up in the presence of water, but to maintain dimensional stability. HMI’s hydro-insensitive foam holds up where other brands fail.

Seawall Repair with HydroFOAM

When you really think of it, water is the root cause of much of the concrete settlement problems with all your work. Poor drainage, voids with freezing water in winter, or countless other scenarios creating fallen or pitched concrete is what lifters and levelers address. In the case of sea walls the problem is on steroids as the concrete or stone barrier is perpetually pounded with tens of thousands of gallons or water with waves, wakes or currents. Often landslide runoff over and behind the wall has the water body reclaiming your customers property. Deterioration and the problems are often first visible as the ground caves in behind the wall and sink hole like depressions become evident.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!

HMI is pleased to announce that we have been certified to NSF/ANSI/CAN-61 for our top selling products RR401 Fast and HF 402. This verifies that our products are safe for use in and around drinking water and other water sources in the United States and Canada through ALS-Truesdail Laboratories. This is a significant milestone in our continued growth and success of our company and of our partners’. This certification shows our commitment to providing our customers with the highest of quality product along with the peace of mind that you are providing your customers with a clean, safe, and sustainable solution.

HF402 is a hydro-insensitive polyurethane foam specifically designed for jobs where water or moisture is present. This 4 lb. per cubic foot foam was designed to set up in the presence of water and to maintain dimensional stability in wet environments. HF402 can be used for residential, commercial and/or industrial applications

HF 402 FAST was formulated to give our customers the great benefits of HF 402 with even more speed.

Deep Foamjection™ is quick, ready to use immediately and long lasting.

HydroFoam can be used for…Tracks, Bridges, Crossings Culverts or anywhere there is a weak sub base present

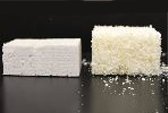

Left Side:

HMI HydroFoam

Right Side:

Competitor #1 Hydro-Insenstive Foam,

30-50% Shrinkage present

Results after 30 Days in water

Left Container:

HMI HydroFoam

Right Container:

Competitor #2 Hydro-Insensitive foam

Immediate Cloudy Water

Left Foam Block:

HMI HydroFoam

Right Foam Block:

Competitor #3 Hydro-Insensitive Foam Crumbles away