Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Grouting equipment is used to install HMI’s Soil Link material. The equipment is simple to operate and typically less expensive than Mudjacking or polyurethane foam concrete raising equipment. You can tackle many different problems, from stopping sea wall soil erosion to increasing slope stability all with the same equipment.

HMI has a few different options depending on material and application needs, with starter kits to ensure you have what you need to tackle your projects. Equipment selection is dependent on grout material. Soil Link Single Component hydro-activated polyurethane or Soil Link Acrylate Grout and volume of material required to be installed.

Learn more about our Soil Link Grout Equipment packages below. For more information on the grout we offer, head to Soil Link Grout.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 1 day, we will teach you what you need to know to successfully tackle ground improvement projects!

HMI is committed to providing grouting equipment systems to meet the diverse needs of ground improvement professionals. Our packages ensure you have the right tools to tackle any project.

HMI Recommended. For installing up to 400 gallons per week. This is a gas powered unit with optional converter for electric operation. Start-up kit includes tools and accessories.

For installing up to 50 gallons per week. This corded unit is electrically operated. Start-up includes kit tools and accessories.

For installing up to 50 gallons per week. This cordless unit is battery operated. Upgrade with a mobile power bank for remote site operation. Start-up kit includes tools and accessories.

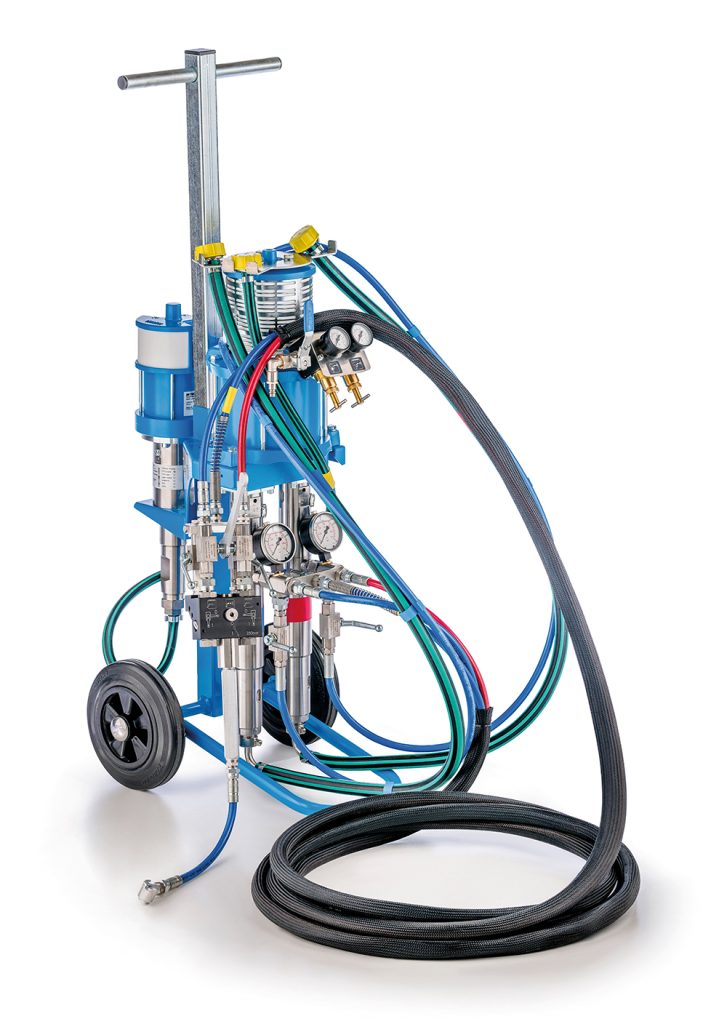

HMI Recommended. Stainless steel two component pneumatic injection pump with flushing capability, free flow 1.5 gpm. Kit includes custom accessories required for ground improvement, crack repair and water control. This pneumatic pump requires an onsite air compressor.

Stainless steel two component pneumatic injection pump with flushing capability, free flow 1.36 gpm. Kit includes custom accessories required for ground improvement, crack repair and water control. This pneumatic pump requires an onsite air compressor.

Whether you’re new to the grouting business or looking to enhance your existing operations, HMI offers top-tier solutions, expert customer and geotechnical engineering support to help you succeed. Our dedicated team is here to provide the guidance and resources you need to thrive in this industry. Get in touch with us today to discover our innovative solutions and learn how we can help you achieve outstanding results.