Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Traditional injection systems rely on large trailers with two bulk tanks. One tank mixes while the other pumps, forcing contractors to manage batches, switch back and forth, and run material through extensive plumbing and many gas powered pumps. These trailers are heavy, complex, and difficult to move between jobsites.

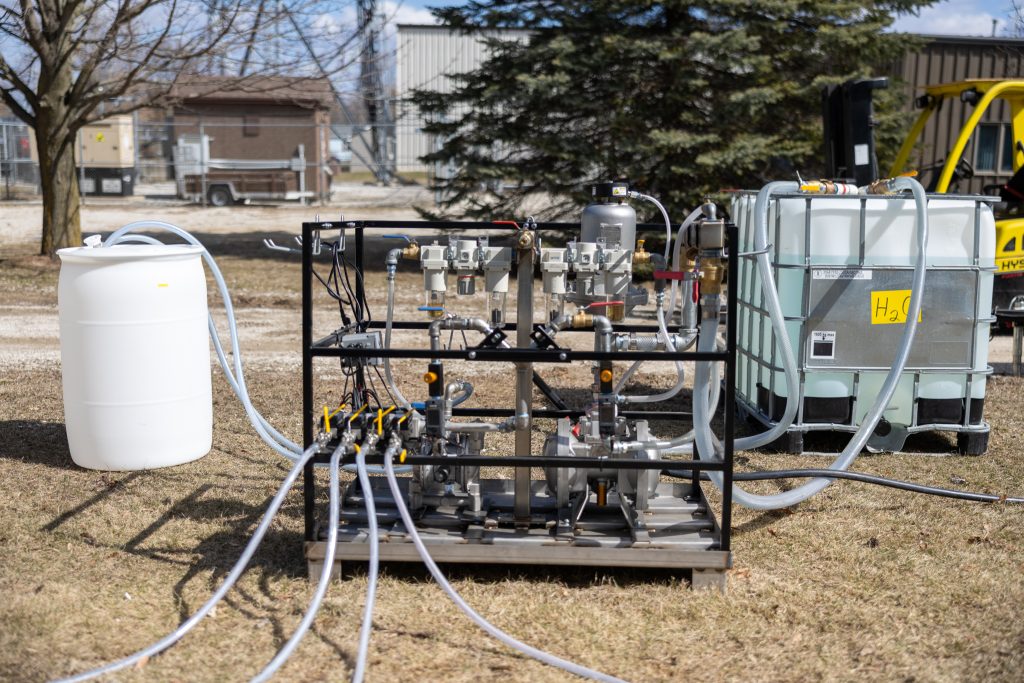

The ICS Injection Equipment replaces all of that with a compact, on-demand system. Instead of bulk tanks, it draws directly from your ICS containers and a water tote or tank, eliminating time-consuming batching and reducing manpower. The unit operates on compressed air and uses115V power for the metering system, making setup simple and reliable.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we will teach you what you need to know to successfully tackle soil improvement projects!

The ICS Injection Equipment is designed for simplicity and precision on the jobsite. Contractors connect one suction line to a water tote or tank and another to the ICS solution container. Pneumatic drives power the pumping system, while the metering system (powered by standard 115V electricity) tracks and displays flow at each injection point.

Operators adjust flow and pressure depending on site conditions — from high output to a controlled drip. With four independent injection lines, multiple points can be treated at once, each monitored by its own flow meter and totalizer to verify exactly how much material has been installed.

At the end of the day, cleanout is simple: place the suction tubes in water, flush the lines, and the system is ready for the next project.

The equipment can be used both in new construction and in remedial applications

To learn more about how ICS prevents clay swelling, please visit our Ionic Clay Stabilizer Material Webpage.

Power Requirements: Pneumatic (compressed air supply) + 115V electric for meters

Injection Points: 4 simultaneous lines with individual shutoff valves

Flow Monitoring: Flow meters and totalizers per injection line

Water Supply: External tote or tank (contractor provided)

ICS Supply: Direct draw from ICS containers

Transport Features: Fork pockets, protective cage, hose storage

Cleanout: Suction tubes placed in water for quick flush

Typical Applications: Pre-construction mixing, in-situ injection, under-slab remediation

At HMI, your operation’s success is our highest priority. Our knowledgeable and experienced team is ready to answer your questions and provide comprehensive support for each project you undertake.

We offer everything from on-site assistance and in-depth equipment training to innovative marketing tools and sales leads. Our goal is to provide you with the expertise and resources necessary to operate a profitable concrete-raising business.

Whether you’re launching a new business or considering expanding your current services, HMI’s experienced staff is committed to helping you build a reliable and reputable operation. We go above and beyond similar companies by understanding your operational needs and providing practical and effective solutions tailored to your requirements.

4466 Custer Street

Manitowoc, WI 54220