How to Use a Dynamic Cone Penetrometer (DCP) for Soil Strength Testing and Subgrade Evaluation

A Dynamic Cone Penetrometer (DCP) is a critical tool for contractors, geotechnical engineers, and site inspectors who need fast, accurate soil strength data. Whether you’re verifying subgrade compaction before paving or diagnosing soft spots in the field, a DCP provides valuable insights in a simple, portable format.

At HMI, we supply both manual and automated DCPs—the Vertek and Pagani models—designed for efficient, reliable operation in real-world testing environments.

What Is a DCP?

A Dynamic Cone Penetrometer measures soil resistance by driving a cone-tipped rod into the ground using a standardized falling weight. By recording how far the cone penetrates per hammer drop, you generate a blow count profile that correlates to the soil’s bearing strength.

Step-by-Step: Performing a Manual DCP Test

- Setup: Assemble the shaft, cone tip, hammer, and handle. Ensure all components are clean and secure.

- Positioning: Place the cone tip on the soil surface vertically.

- Initial Drop: Perform a seating blow to eliminate surface fluff or organic matter.

- Testing:

- Drop the hammer from the specified height.

- Use the rod’s built-in depth markings to record penetration after each drop.

- Repeat until refusal or target depth is reached.

- Data Collection: Log depth per blow to evaluate compaction and locate weak zones.

Understanding Blow Counts: What the Numbers Tell You

DCP testing offers immediate visual and numerical data for assessing soil conditions:

- Low blow counts (fewer than 3 blows per 4 in): indicate loose or weak soils and may suggest the need for soil stabilization.

- High blow counts (more than 10 blows per 4 in): suggest dense, well-compacted subgrade, typically suitable for structural support.

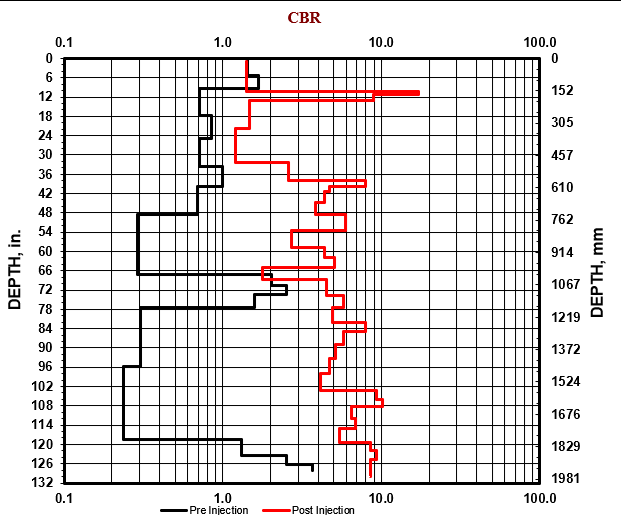

This data helps guide decisions for pavement design, site prep, or remediation planning. In areas with persistently low blow counts, chemical grouting may be considered to densify the soil and improve load-bearing performance prior to construction or repair.

Tips for Accurate Results

- Let the hammer fall freely—avoid controlling the drop.

- Use consistent rhythm and pause briefly between drops.

- Inspect rods, tips, and hammer faces routinely for wear or deformation.

Safety and Maintenance

- Wear safety gloves and eye protection.

- Avoid placing hands near the anvil or shaft while in use.

- Clean the equipment after each use to prevent buildup or binding.

HMI’s DCP Equipment and Support

We offer two premium DCP units tailored to different testing needs:

- Vertek Manual DCP – A field-proven, hand-operated DCP ideal for general soil testing, subgrade evaluation, and on-site compaction checks. Portable and dependable, it’s built for contractors who need mobility and quick deployment.

- Pagani Automated DCP – A high-precision, hydraulically-operated unit that raises and drops the weight via foot pedal controls. Ideal for engineering firms and municipalities, it delivers consistent blow counts, supports deeper testing, and reduces operator fatigue.

Both models are supported by HMI’s expert technical team. We offer guidance, resources, and replacement parts to keep your field work efficient and accurate.

Ready to Learn More?

Visit our DCP Equipment Page to explore detailed specs, videos, and ordering options. Whether you need basic compaction testing or advanced profiling, HMI has the tools to help you get the job done right.