Understanding Deep Foamjection™

Jen Mazur

Professional concrete lifting contractors look for the most effective solutions to sinking foundations, sidewalks, patios and slabs. There are many deep injection concrete lifting products on the market, but not all of them provide the same results to meet customer expectations. HMI helps you grow your deep polyurethane injection business with an overview of Deep Foamjection™ and how it compares to alternative solutions.

An Effective Resource for Concrete Lifting Projects

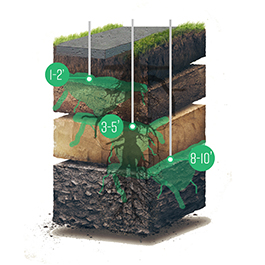

Deep Foamjection works by binding soils and enhancing compaction in the treatment area. The goal of the product is to enhance the environment surrounding a concrete slab, enabling individuals to continue using the space. Users should inject and apply the soil stabilization foam in multiple layers of soil underneath the slab for optimal results in the field.

When to Use Deep Foamjection

Using Deep Foamjection can give your concrete lifting business a competitive edge. Deep Foamjection products focus on solving the root cause of sinking concrete — by stabilizing soil and substrate layers at several points far below a structure.

Deep Foamjection can stabilize soil to the point that it stops these substrate layers from worsening, whereas traditional polyurethane only lifts a slab close to the underside surfaces. With traditional polyurethane, businesses must consider both the age and condition of the concrete they are using. A compaction grouting alternative, such as Deep Foamjection, focuses more on what is happening several feet below the slab, adopting a proactive approach to repairs.

Your concrete lifting business may turn to Deep Foamjection when facing tight deadlines. The process involves injecting material into the ground instead of installing physical structures, which is necessary for piering.

Indicators That Deep Foamjection Is Needed

Rely on HMI for Deep Foamjection when your team notices:

- Recurring settlement following shallow lifts.

- Voids beyond the slab interface.

- Loose fill around slabs.

- Heavy impact loads near concrete (loading docks).

Common Application Sites for Deep Foamjection

Consider HMI solutions when working on repairs and surface maintenance near:

- Warehouse slabs.

- Bridges and roads.

- Airport runways.

- Seawalls and bulkheads.

- Embankments.

- Culverts and drainage structures.

- Commercial and residential additions.

HMI’s Deep Foamjection Differentiators

HMI offers Deep Foamjection solutions to support contractors and businesses. Our Deep Foamjection uses a specialized HydroFoam that is appropriate for wet soil conditions. Regardless of recent weather patterns and moisture levels, users can rely on Deep Foamjection to respond properly when water is present in the soil.

HMI offers the EliteONE gun for a streamlined injection process. Individuals can apply the soil compaction material at multiple points with a handheld tool that purges air and allows for repeated injections across a quick-connect pipe system. Apply Deep Foamjection to improve the weight-bearing capacity of soils without clogging equipment.

Engineering Guidelines for Deep Foamjection

Many concrete lifting and stabilizing projects can be completed without the help of an engineer. This is often the case for smaller slabs and structures. However, HMI offers multiple training and support opportunities for those who are new to concrete lifting, as well as teams interested in expanding their offerings to customers.

From two-day training sessions and engineering support to on-site and crew shadowing opportunities, we provide options to help your business better understand project requirements and determine the most effective remediation strategies.

Contact HMI for Deep Foamjection Solutions

HMI offers the support, products and training you need to fine-tune your concrete lifting and soil compacting process. Our experts have over 50 years of experience to help you make the right decisions when serving your customers. You can contact HMI to learn more about Deep Foamjection solutions today.