Transform your concrete lifting experience with a polyurethane gun specifically designed by concrete lifting specialists to improve precision and efficiency.

Brian Cvetezar

Paul DelFino

Ever since polyurethane was first used to lift and level concrete decades ago, practitioners have used equipment designed for spraying polyurethane — not for injecting it under concrete. That was the case until HMI engineered a user-friendly concrete lifting injection gun.

Concrete Lifting With a Gun Makes All the Difference

Anyone who has worked in the industry will testify that, assuming you are using the correct foam, the trick to productivity in polyurethane concrete lifting is controlling the lift with a gun. Most often, polyurethane concrete lifters have been using one of two great Graco products for injecting polyurethane under concrete: the GX7 or the Fusion gun.

The GX7

The GX7 is a great spray foam tool. However, since it doesn’t apply an air-purged system, it is like a “One and Done, Single Shot Revolver” for concrete lifting. If you do not get the exact lift you want, you will find yourself continually redrilling holes as you attempt to feather and finesse a slab where you want it.

The Fusion Gun

The Graco Fusion gun deploys an air purge system with a continuous flow of air in the injection hole, allowing for repetitive and ongoing injection of material under concrete to control the lift. However, the Fusion gun is a much more complex tool with a multitude of parts and O-rings.

Maintenance is expensive, and it is prone to backup and clogging under the back pressures often experienced in concrete lifting. Some have described working with a Fusion gun that is not equipped with an HMI front end as: “Going into battle with a weapon sure to jam just when you need it.”

In 2012, HMI introduced a specially engineered front end for the Fusion gun to improve its reliability, but opportunities for improvement still existed.

Engineering a Unique Concrete Lifting Injection Gun

Very often, the solution to a problem is to just start from scratch. In 2013, HMI began the journey of developing a polyurethane injection gun that would approach perfection for concrete lifting and leveling. The resulting product features the following:

An Air Purge System

This feature gives the operator maximum control while preventing clogging. It uses compressed air to clean out the gun’s internal mixing chamber before any residual mixed material can solidify.

By giving the operator separate control over the air and material flow, they can:

- Inject small, controlled bursts of foam to level a slab perfectly.

- Use air to keep the injection port open and prevents backup for a clean, effective lift.

- Control the timing and duration of the air purge to ensure a perfect clean out of the mixing chamber.

Integrated Gauges for Real-Time Pressure Monitoring

Our concrete lifting injection gun features dials at the point of injection so an operator can monitor all aspects of performance. The gauges display the real-time fluid pressure, allowing the operator to confirm that the two chemical components are flowing at the recommended pressure to ensure a precise 1:1 ratio.

Without the gauges, an operator may unknowingly inject off-ratio foam if the pressure drops due to a hose blockage. This mixture would not cure properly, leading to wasted material. With pressure gauges, the operator can see a pressure imbalance and stop the injection immediately.

A Simple Design Featuring Limited Parts

We engineered our EliteONE polyurethane gun with fewer replacement parts to reduce the cost of ownership and operation over its lifespan. When it comes to ease of maintenance, the air purge system prevents clogging and makes the gun easy to clean, meaning more uptime for you to complete more projects and generate more revenue.

Ergonomic Comfort and Ease of Fastening to Concrete Injection Ports

The handle fits comfortably in the operator’s hand, minimizing fatigue during long hours. Our concrete lifting injection gun also features a quick-connect system that permits the operator to securely attach and detach the gun from the ports with minimal effort. This design speeds up workflow since the operator can move from one injection point to the next rapidly and efficiently.

Intentional Engineering That Prevents Backup

EliteONE features internal mechanisms that prevent the higher-pressure chemical from being forced into the other chemical’s hose, ruining the entire length of the hose. This design element makes our injection gun a dependable tool that resists failure and performs as expected.

The EliteONE Polyurethane Gun vs. GX7 and the Fusion Gun

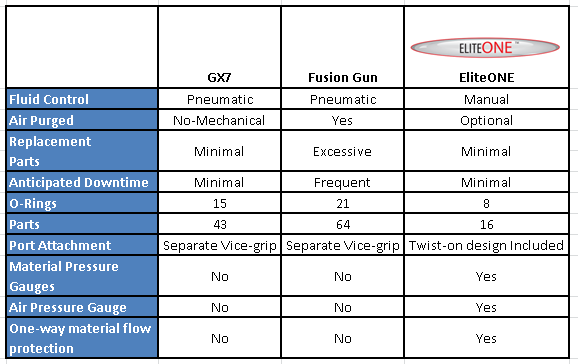

The chart below demonstrates how our injection gun compares to competitors.

Seeing is believing. Watch our introductory video

Slab Lifting Gun Maintenance for an Extended Lifespan

You must clean EliteONE daily to maintain optimal performance. Daily maintenance checklist:

- Purging: Do a final air purge to clear the tip and wipe down the exterior with a rag and cleaner.

- Disconnecting: Turn off the transfer pumps, shut off the main air supply and disconnect the fluid hoses.

- Disassembling: Disassemble the front-end components for cleaning.

- Cleaning: Using a cleaner and cleaning tools, remove any uncured residue from the components.

- Inspecting the air passage: While still disassembled, reconnect the air line to check air stream strength.

- Lubricating: Apply a thin layer of lubricant to the parts to ensure smooth operation and easy disassembly at the next job.

- Reassembling: Reassemble the components and avoid overtightening.

During weekly maintenance sessions, perform a deeper component inspection and cleaning according to the manual and reapply lubricant.

Transform Concrete Lifting Jobs With EliteONE

Tired of equipment that can’t keep up? EliteONE is engineered to increase reliability and safeguard your bottom line. Our clients experience dramatically easier maintenance and zero backup issues, demonstrating that simplicity and innovative engineering can truly make a difference.

Call 888-793-9484 today or contact us online to get started. We back our products with exceptional customer service, including hands-on training support and flexible financing plans.

About the Authors

Brian Cvetezar is an owner of HMI and RaiseRite Concrete Lifting. He is acknowledged as an industry expert, having managed tens of thousands of projects worldwide involving the lifting and leveling of millions of square feet of concrete. His responsibilities at HMI include product development and specialty–foam formulation. Within HMI, Brian is affectionately known to be “The Father of the EliteONE!

Paul DelFino is a principal of the consulting firm Opportunity Inc. For nearly two decades he has assisted entrepreneurs in growing their businesses, responding to economic downturns and merger and acquisition activity. He has consulted with HMI and RaiseRite for over a decade. His publications include “Avoiding Skewed Entrepreneurial Strategies” available from all online booksellers.