Deep Foamjection™ and Moisture: Why Foam Chemistry Matters More Than Ever

In Deep Foamjection™, we stabilize and strengthen soils deep beneath the surface — often in environments where ground moisture, high water tables, or nearby bodies of water present unique challenges. While many polyurethane foams are marketed as “hydrophobic,” not all are truly suited for saturated soil conditions.

The reality is, not all dual-component polyurethane systems are created equal — and understanding that difference is crucial for consistent, reliable ground improvement.

The Problem with Moisture and Petroleum-Based Foams

Polyurethane foam forms when two components — an isocyanate (A side) and a polyol blend (B side) — react together. In dry ground, this process is controlled and predictable. But in wet or saturated conditions, groundwater becomes an uninvited participant in that reaction.

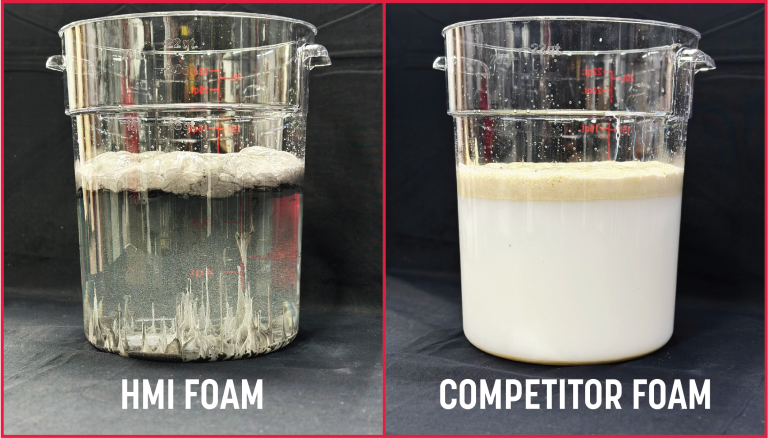

Most petroleum-based foams, while hydrophobic when cured, aren’t moisture-tolerant during the reaction. Water in the soil begins reacting with the polyol, upsetting the A/B ratio and leading to:

- Inconsistent foam expansion and density

- Reduced yield and structural integrity

- Uncontrolled reaction byproducts

- And potentially, chemical leaching into surrounding groundwater

In Deep Foamjection™ applications, where injections occur at depth and across variable soil conditions, those inconsistencies can undermine the uniform soil-polyurethane matrix we aim to create.

HMI®’s Bio-Based Foam: Designed for Moisture-Rich Environments

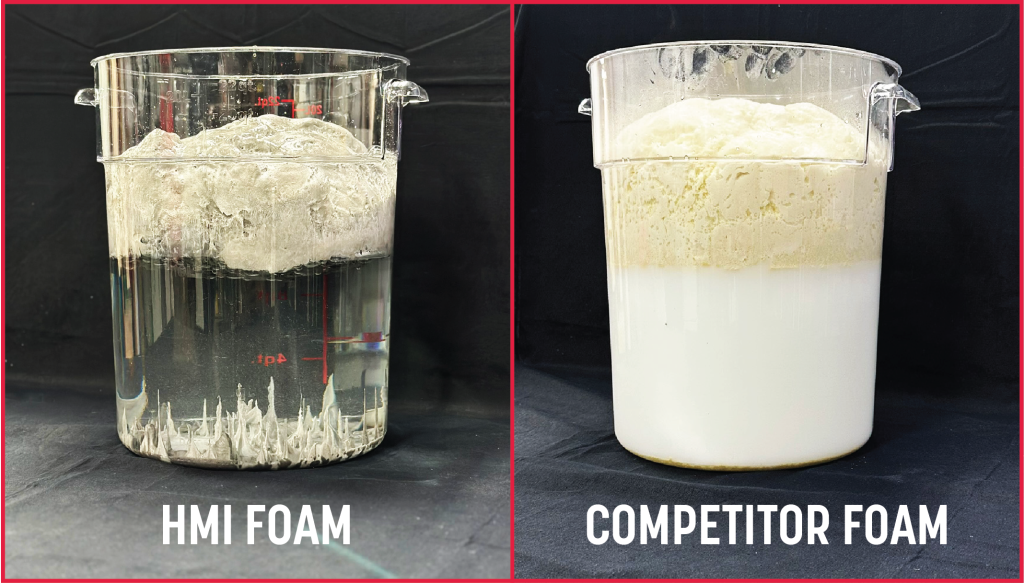

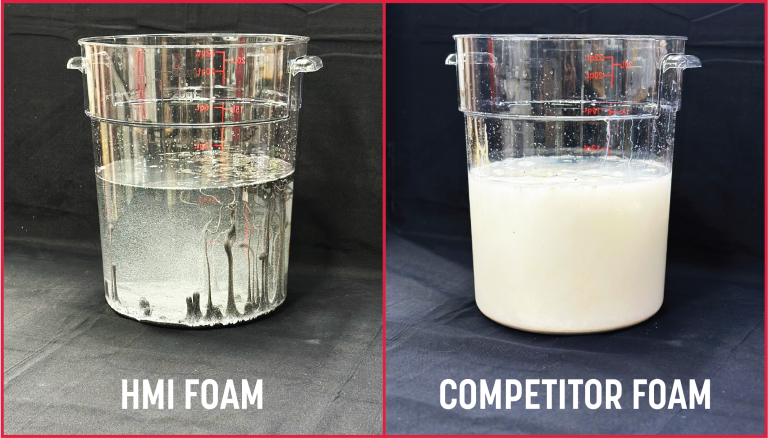

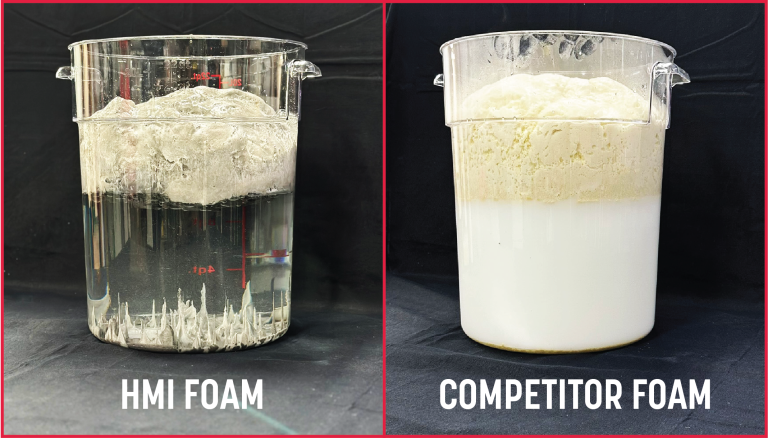

HMI®’s bio-based polyurethane foams are engineered specifically for these conditions. Our formulations are hydrophobic before and after reaction— meaning moisture in the ground does not interfere with the foam’s chemistry or performance.

This ensures:

- Stable A/B ratio control

- Consistent reaction and yield

- Predictable expansion and soil bonding

- No environmental leaching

Rather than reacting with groundwater, HMI foam simply displaces it, forming a strong, uniform foam structure that bonds with surrounding soils — even in fully saturated zones.

The Bottom Line

When working in high-moisture or variable ground environments — near lakes, rivers, or shallow water tables —foam chemistry is non-negotiable. Using the wrong material can compromise both performance and environmental safety.

That’s why HMI’s bio-based hydrophobic foams are the professional’s choice for Deep Foamjection™. They’re designed to maintain yield, structure, and safety — no matter the soil conditions.