Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Learning & Resources » Case Studies » Firehouse Settlement

A firehouse in Las Vegas, Nevada had suffered from extreme settlement. This firehouse is essential to the community and was not able to shutdown. Piers were chosen to correct this settlement. The highest lift was 7 inches leaving a considerable void under the floor

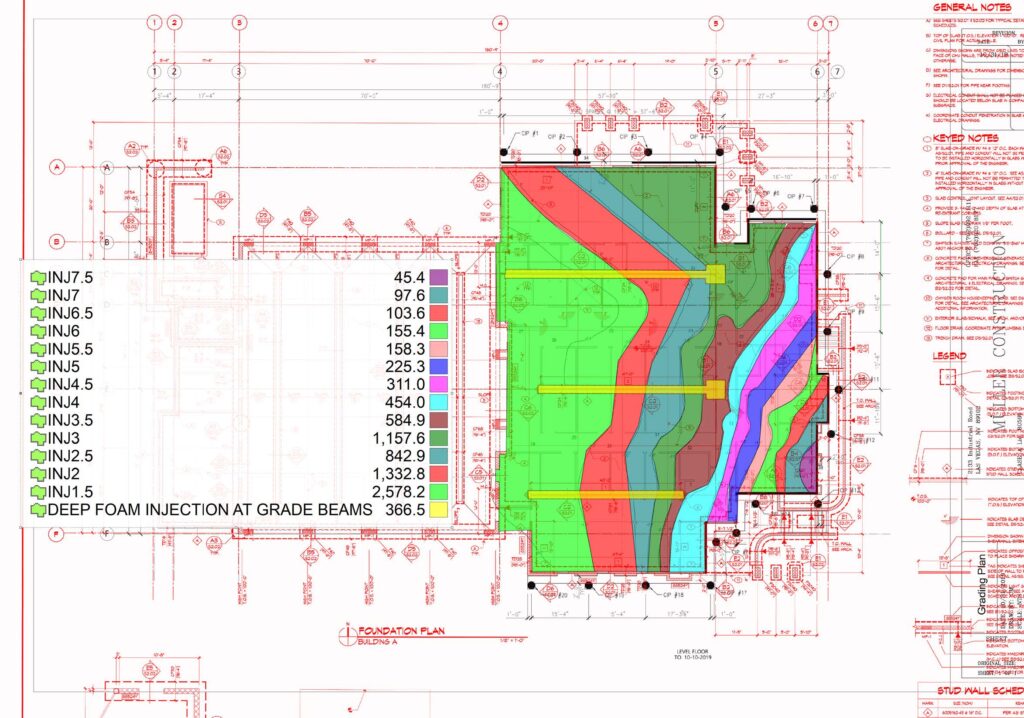

A local concrete lifting company was chosen to fill this void. They drilled 5/8th inch holes where the structure needed to be lifted in a 4 foot grid. The team planned to lift the building in stages, 2 inches at a time. After 2 inches of lift, they filled the void under the floor so it was supported during the lifting process. This continued until the structure was at the correct height. In addition to piering the exterior 7 inches, there were three grade beams that ran through the firehouse that needed to be lifted. Without shutting down the building to the firefighter crew, it was not possible to pier the grade beams like they could with the exterior walls. The solution to this was to use the HMI Deep Foamjection™ process. Drilling 5/8 inch holes throughout the grade beams and into the soil below. Multiple Deep Foamjection™ pipes were installed, starting at the lowest spot of the grade beam to inject material. The first grade beam was down 2 inches. Once lifted, the void was filled between the exterior wall and grade beam. Another support beam was below the sleeping corridors and restrooms for the firehouse. A plumber marked out where the pipes were so they knew where to safely drill the holes.

HMI Polyurethane void filling was the best solution for the firehouse to stay in operation. The holes were drilled ahead of time to save time. The firefighters were able to continue using the sleeping corridors and restroom as this project was in progress. This project was completed in 10 days while keeping the firehouse fully operational. Three beams were lifted successfully and all voids were filled in this 8,400 square foot building. 15,000 pounds of material were used to complete this project. The two HMI polyurethanes used to complete the project were RR401 and HF402.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!

4466 Custer Street

Manitowoc, WI 54220