Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Learning & Resources » Case Studies » Grain Bin – Deep Foamjection™ Stabilization and Raising Project

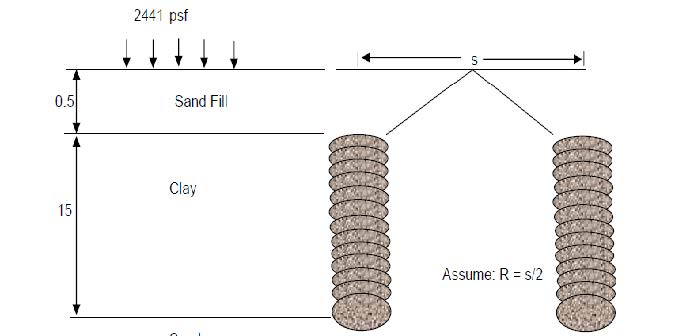

Located in Cedar, Kansas, this 150,000 bushel capacity grain bin was constructed in 2010 over a Geopier-reinforced subgrade. The slab was constructed with a ring footing foundation on a 6” thick floor over a 6” base of granular fill. At full capacity, the grain load for this bin is 2,441 psf with a total weight of 4,600 tons which the combination of subgrade and geopiers we unable to support.

Soil analysis identified a top layer of sand fill with 15 feet of clay/silt. With known layers of unstable soils and failed attempts to support the grain bin, the failed soils needed to be repaired.

Utilizing geotechnical reports, HMI aided the contractor in a project design to stabilize the subgrade and also lift the settled slab.

Previously installed geopiers had been installed at a depth of 15 feet. In conjunction with the weak subgrade, there was not enough strength to support the full weight of the filled grain bin, Half of the slab settled by 6 inches.

The full repair would require to first stabilize the subgrade, then attempt to lift the settled slab up to 6 inches. Alternative repair methods were bid exceeding $1M with months of demolition and construction. With fall harvest approaching this repair was time sensitive.

A four foot grid pattern of 106 points were used to install Hydrofoam 402 at a depth of 12-15 feet to stabilize the soil. Each injection point accepted 15-75 pounds of material as noted in the color-coded chart below. Using an HMI EliteONE injection gun, a total amount of 4,500 pounds of HF402 foam was incrementally installed into the soil to stabilize the subgrade. HF402 was chosen for stabilization due to the potential water present, strength and the ideal reaction profile for Deep Foamjection™.

HF 402 has a minimum PSI of 124 or 17,856 PSF with a slow reaction profile to allow the foam to travel further. By volume, the foam installed to stabilize soils was equal 1,125 cubic feet of foam. After the material was installed, the above grade pipes were cut and the holes patched.

After the soil was stabilized, 62 holes (5/8”) were drilled to pump material for lifting through injection ports. To lift, 4,500 pounds of HF 402 Fast and 1,000 pounds of RR 401 were used, achieving a 5 inch lift. At this point, the slab was demonstrating signs of stress and the customer was pleased with conclusion of project. The foam used to lift the slab was equivalent to 1,375 cubic feet in volume.

A total of 10,000 lbs were used to stabilize and lift the slab. This volume of 2,500 cubic feet of foam is equivalent to the volume of an Olympic sized pool.

In total, this project took 5 days to drill, stabilize, lift and complete, saving the owners months of downtime and hundreds of thousands of dollars.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!

4466 Custer Street

Manitowoc, WI 54220