Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Learning & Resources » Case Studies » St. Petersburg Seawall Repair Case Study

Single Component Polyurethane: Ideal solution for sealing cracks, stabilizing soils, and extending the lifespan of sea walls.

A residential coastal seawall in St. Petersburg, Florida was exhibiting signs of soil loss (soil piping) from underneath the seawall and through gaps or cracks that slowly developed over time. This soil loss resulted in settlement of the retained soil, with very loose soil and small voids encountered at depths from 3 to 6 feet and 7 to 10 feet below the top of grade, which compromised stability of the seawall. A previous stabilization attempt involved the installation of 3 piers driven against the face of the seawall to provide additional lateral support. However, this approach did not address the root cause – ongoing soil loss.

The situation was further exacerbated over time by the large tidal fluctuations common to the area, which continued to pipe soil through and beneath the seawall. The initial proposed repair solution was to replace the seawall or to continually backfill the settled areas behind the wall with seashells throughout the lifespan of the structure. A cost-effective ground improvement solution of foam injection behind the seawall was proposed, aimed to prevent further soil loss, increase stability of the retained soil, and extend the lifespan of the seawall.

To address the soil piping and stabilize the soil behind the seawall, the decision was made to conduct permeation grouting using a single-component polyurethane foam. This material was chosen for its effectiveness in stabilizing soil, filling cracks and voids, while being minimally invasive with no excavation or large equipment. The ability to adjust the reaction time on-site, through mixing adjustable amounts of catalyst, would allow the material to permeate through the soil, ensuring comprehensive coverage. The permeated material would also penetrate unseen gaps or cracks beneath the waterline before expanding to seal off those channels for soil loss. (As pictured below)

In addition, a slower reacting foam exerts a very low expansive pressure, which was desired to allow for injections next to the seawall to take place without the concern of high expansive forces pushing on the distressed wall.

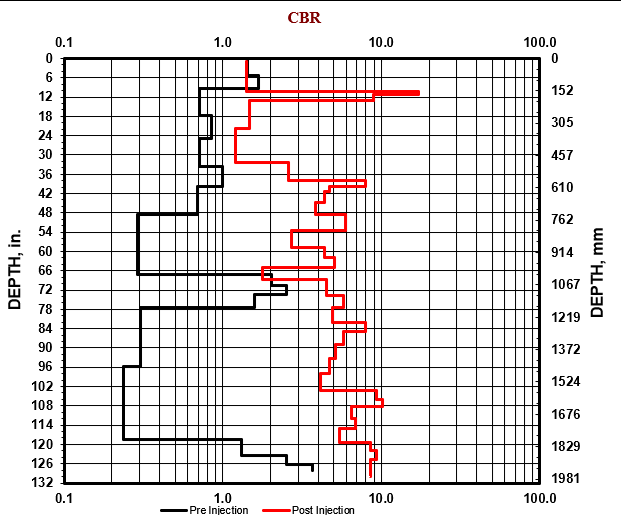

An engineered plan, determined by pre-injection DCP (Dynamic Cone Penetrometer) and probe testing, resulted in injection probes that were driven to a depth of 10 feet below grade spaced approximately 1.5 feet on center. The material was pumped using a lightweight and portable specialized airless paint sprayer. Pre-determined volumes of foam were injected from the depth of 10 feet to 3 feet below the top of grade before moving to the next probe. Approximately 155 linear feet of seawall was treated using this method. After completion of injection a Dynamic Cone Penetrometer (DCP) test was repeated to provide an assessment on the effectiveness of the soil improvement.

Comparisons of the DCP test results before and after injection showed a 699% improvement in the California Bearing Ratio (CBR) between the treated depths of 3 to 10 feet at the first location and a 277% improvement at the second location. The injection process effectively addressed the underlying soil piping issue, improved the stability of the loose soil behind the seawall, and provided a long-lasting solution with no environmental impact by plugging spots of water ingress and filling voids. The success of this project demonstrates the viability of single component polyurethane foam as a repair material for similar coastal infrastructure challenges.

Post Hurricane Helene and Milton Update.

In June 2024, permeation grouting using HMI’s single component polyurethane foam was completed on the subject seawall just ahead of the hurricane season. When catastrophic Hurricanes Helene and Milton struck within a two-week period – producing storm surges that exceeded the wall’s height – the treated seawall held firm. Unfortunately, many neighboring untreated seawalls experienced catastrophic failures from soil loss near the bottom of the wall (as seen in photos). However, the treated seawall remained intact with no observable soil loss or wall movement.

HMI’s repair methodology accurately identified the necessary treatment depths and

potential failure mechanisms during the initial assessment before grouting with our single component polyurethane foam. Comparative DCP tests, conducted before and after the injections, confirmed a significant increase in soil strength to increase global stability of the seawall. We are proud to say that the HMI seawall repair methodology not only stabilized and extended the lifespan of the seawall but also prevented a catastrophic failure.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!

4466 Custer Street

Manitowoc, WI 54220