Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Learning & Resources » Case Studies » Telecommunications Facility Case Study

Soil Link™ Acrylate Grout: Crack Sealing and Water Infiltration Prevention

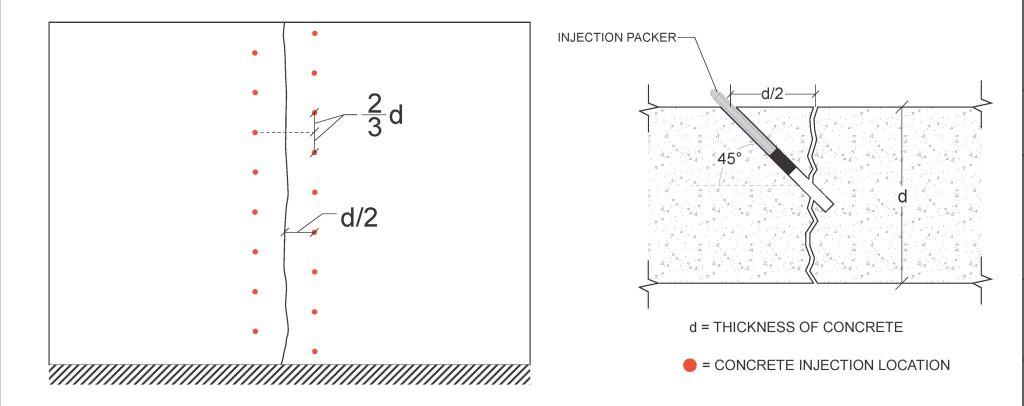

A telecommunications switching station was facing chronic groundwater infiltration that threatened highly sensitive electrical equipment. The water intrusion stemmed from foundation settlement and was traced to four significant cracks in the structure’s thick concrete walls:

• Two full-length cracks (10 feet each)

• Two six-foot cracks, one of which was actively leaking

Unlike residential foundations, the unusually thick walls at this facility presented added complexity in sealing efforts. A long-lasting, fail-safe waterproofing solution was critical to prevent operational disruptions.

Due to the age of the wall, thickness, and the need for a permanent solution without error to protect sensitive electrical equipment, a geotechnical engineer recommended HMI’s Soil Link™ Acrylate Grout to provide a watertight seal.

The standard six-step interception process was modified to have an acid flush instead of water, when water testing, to ensure adherence by first cleaning the cracks of any dirt, organics, mold and debris built up over the many years. Hydraulic cement was also used when sealing the crack with an active water leak to ensure seal adherence.

The cracks were successfully sealed with HMI’s Soil Link™ Acrylate Grout stopping water infiltration in its tracks. After an acid base flush cleaned out dirt, organics and debris, the low-viscosity acrylate gel effectively permeated the narrow and leaking cracks, forming a long-lasting waterproof barrier. Thus, effectively protecting the sensitive electrical equipment and solving the problem.

As a preventative measure, proper grading was performed after crack sealing by raising the concrete against the facility with HMI HF402 to help mitigate future settlement causing foundation cracking and control water flow.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we will teach you what you need to know to successfully tackle soil improvement projects!

4466 Custer Street

Manitowoc, WI 54220