Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Home » Equipment » Industry Leading Polyurethane » HMI Hydrofoam Line

When handling seawall repairs, a hydrophobic polyurethane foam is needed. Thanks to HMI, you can get a hydro-insensitive foam that continues to perform after frequent water exposure. The days of troubleshooting seawalls and concrete repairs in aquatic environments are behind you, as you can complete projects without clouding water, contaminating resources, or crumbling or shrinking in the future.

Our product line covers the injection, reaction and curing phases, and it is precisely what you need to complete the most complex seawall repair work.

HMI noticed a gap in the available options for polyurethane concrete repairs in locations close to water. We developed our HydroFoam line to resist hydrolysis, which is when water breaks down another substance. With foam, water interferes with the integrity of the foam bond, and the material shrinks over time. We separate our HydroFoam from other solutions on the market, as professionals can apply the foam in the presence of liquid without compromising the material’s dimensional stability.

Seawall repairs can be tricky, as the right material is needed to facilitate drainage, prevent water from freezing underneath slabs and keep surfaces level. These surfaces can encounter tens of thousands of gallons of water.

Traditional polyurethane is water-resistant, but HMI’s HydroFoam provides extra peace of mind that repairs can withstand wakes, waves and currents, as well as stop premature sinking when used correctly.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!

HMI works hard to maintain its impressive reputation in the concrete lifting space. Our products are developed for widespread use, and select polyurethane-based offerings meet NSF/ANSI/CAN-61 certification requirements. Specifically, our HF402 and HF402 Fast materials can be used in applications near drinking water and public water sources.

We are committed to our clients, and you can rely on us for polyurethane foam solutions that contribute to others’ safety and an organization’s sustainable practices.

Our team developed multiple types of HydroFoam for widespread use cases:

This polyurethane foam is ideal for moist or damp residential, commercial and industrial environments. It is a 3lb foam with 23 times expansion.

Get everything you like about the HF302 HydroFoam with an even faster curing time and minimized spread.

This polyurethane foam is ideal for moist or damp residential, commercial and industrial environments. Our flagship HydroFoam with NSF certification and offers users exceptional stability, even when water reaches an injection site. It is a 4lb foam with 16 times expansion.

Get everything you like about the HF402 HydroFoam with an even faster curing time and minimized spread.

Deep Foamjection™ is quick, ready to use immediately and long-lasting.

HydroFoam can be used for tracks, bridges, crossings, culverts and anywhere there is a weak sub-base.

Left Side:

HMI HydroFoam

Right Side:

Competitor #1 Hydro-Insenstive Foam,

30-50% Shrinkage present

Results after 30 Days in water

Left Container:

HMI HydroFoam

Right Container:

Competitor #2 Hydro-Insensitive foam

Immediate Cloudy Water

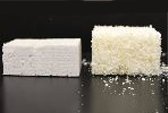

Left Foam Block:

HMI HydroFoam

Right Foam Block:

Competitor #3 Hydro-Insensitive Foam Crumbles away

Interested in seeing our hydrophobic polyurethane foam in action? We put together some videos to show how effective our solutions are in real-world situations.

At HMI, we enjoy helping clients make the right selections for specific projects. We use over 50 years of industry experience to develop innovative foams for concrete lifting in the most demanding environments. Reach out to us for more about our offerings today.

4466 Custer Street

Manitowoc, WI 54220