Cookies & Your Privacy

This website uses cookies to ensure you get the best experience on our website. More Information >

Your contracting business requires polyurethane concrete raising foam at reasonable costs. If you’re searching for where to buy concrete lifting foam or need polyurethane foam for lifting concrete, HMI is your one-stop solution for premium foam materials and concrete raising equipment to finish work efficiently.

HMI developed and designed the only foam on the market utilizing renewable components. One of the benefits of raising concrete with polyurethane is the availability of reliable material. Our eco-friendly foam materials are specifically designed for different applications. From lightweight residential concrete raising and highways to industrial flow projects, underwater settings and loose soil stabilizations, the HMI poly difference is in the results. Whether you’re performing foam concrete lifting on residential driveways or using concrete leveling foam for commercial applications, our eco-friendly materials are specifically designed for different applications.

Clients depend on us for dual-component foam featuring a 1:1 ratio. With the correct training, your contracting business and team can inject eco-friendly foam underneath sinking concrete. The user-friendly process allows you to eliminate voids, compact soils and lift concrete as the foam expands and changes from a liquid into a solid form. Professionals just need to monitor equipment pressure readings and make adjustments as needed.

This site is protected by reCAPTCHA and the

Google Privacy Policy and Terms of Services apply.

In 2 days, we teach you everything you need to know to start your own concrete raising company!

Our eco-friendly foam is available in several product lines to meet your project demands. Our experts understand every concrete lifting project is one-of-a-kind. Use the details below to select the best polyurethane foam offering for your responsibilities and spending budget.

This line of foam products is formulated using environmentally responsible, renewable and recycled materials. With a significant amount of biobased content, foams from this product line achieve USDA Certified Biobased Product approvals. Additionally, the recycled components are supercharged with catalysts, providing unmatched reaction times while reducing the need for petroleum-based raw materials.

USA MADE & GREEN

HMI Hydrofoams are formulated with new raw materials, unlike our Recycled Line. The Hydrofoam line is designed to set up in water with great dimensional stability and without shrinking. This is called hydro-insensitive or hydro-phobic. Hydrofoam is designed specifically for sub-grade applications when exposed to groundwater (Deep Foamjection™).

HMI Specialty Material products also feature environmentally responsible, renewable and recycled materials. Biobased content is included within the foam, helping it achieve USDA Certified Biobased Product approvals. The recycled components within HMI Specialty Material products are supercharged, allowing them to provide unparalleled reaction times. Similar to our Recycled Foam Line, there is a lesser need to use petroleum-focused materials during projects.

HMI professionals believe finding dependable polyurethane foams, equipment and training should be easy. Aside from offering equipment and supplies for any concrete raising project, we provide you with the resources necessary for starting your own business or expanding your current skill set.

We’re your source for foams appropriate for the residential, commercial, industrial and government sectors. Our team is constantly looking for ways to innovate and offer the highest level of service for entrepreneurs, startups, established business owners and government entities. When you purchase concrete raising equipment and materials from HMI, you’re ready to work the moment you step foot on site.

Should you need us for training, project or engineering assistance, we have your back. Sidestep challenges in the concrete raising industry thanks to experts who channel five decades of experience to help you succeed.

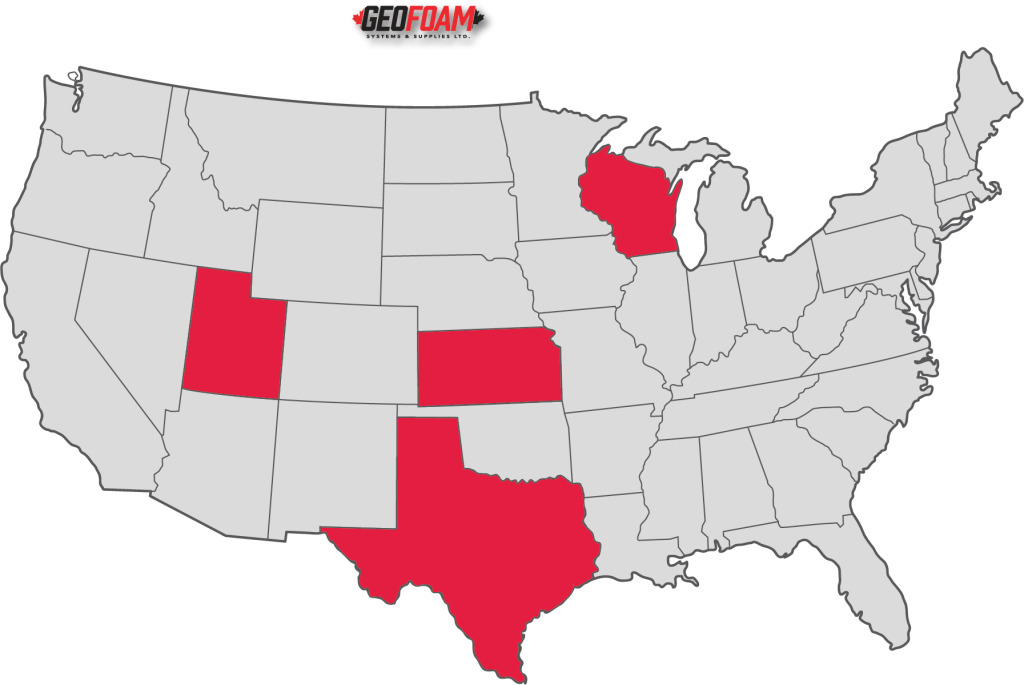

HMI operates 5 foam concrete lifting distribution centers across North America, making it convenient to find where to buy concrete lifting foam near your location.

Unlock the potential of your projects with HMI’s industry-leading polyurethane foam solutions. Our high-performance materials are designed to provide exceptional durability and support, making them ideal for a variety of applications, including concrete raising. Our innovative products can help you achieve outstanding results.

Ready to improve your process for completing concrete restoration work? Don’t wait — reach out today to learn where to buy concrete lifting foam, explore our polyurethane foam for lifting concrete options, or purchase concrete leveling foam materials today.

4466 Custer Street

Manitowoc, WI 54220